The ARISS website reports on progress towards flying new amateur radio equipment to the International Space Station.

On behalf of the ARISS International team, I am proud to announce that on Friday September 29th the ARISS team submitted the InterOperable Radio System (IORS) Safety Data Package to NASA for review! Our next step in this process is the Safety Review, which is planned for November 2.

Submitting this was a phenomenal accomplishment!! Particularly since the entire Safety Data Package was developed exclusively by our ARISS volunteers—something we have never done before. Prior to this submittal, all safety packages—from Owen Garriott’s in the early 1980s to today–were developed with contractors from NASA, ESA or Energia. And might I say at substantial expense. I am pleased that the ARISS team did it ourselves!

Why is this important? Two reasons:

1) This is a very major IORS milestone. We cannot get to orbit without successfully completing the safety review process and getting our hardware certified for flight.

2) Developing the safety package exclusively with volunteers is an innovative and gutsy approach to keep costs down and get the hardware flown sooner. Otherwise we probably would have to slip launch 1-2 years while we acquired additional funding to get this done.

NASA Human Spaceflight Safety Certification is a four-step process—Phase 0, Phase 1, Phase 2 and Phase 3. The material we submitted covers the first three of the four phases. As part of Phases 0, 1 and 2, we need to make sure NASA understands our design. And we need to show NASA that we understand all the potential hazards that our hardware systems could introduce to ISS and how we have mitigated (or prevented) these hazards. One example is to demonstrate to NASA that our IORS was designed with electrical wiring and circuit breakers that possess adequate features and sufficient margin to prevent an electrical shock or fire on-board the ISS. Critically important stuff! The final phase (Phase 3) will be complete when we have completed all testing and NASA inspection of our flight hardware and NASA deems it flight worthy. At that point the IORS will be flight certificated and we can fly! Currently we are looking to March-May 2018 for flight readiness.

For those not following ARISS hardware development very closely, we are developing the IORS to replace most of the on-board radio hardware. It is called “interoperable” because it is being designed to be operated anywhere on ISS. But specifically, it will be used in the two areas with ISS Ham legacy antennas: the Columbus Module and the Russian Service Module. Interoperability allows us to leverage existing ISS power cables, it can be moved between modules in the event of on-orbit failures, and it supports common training and operations.

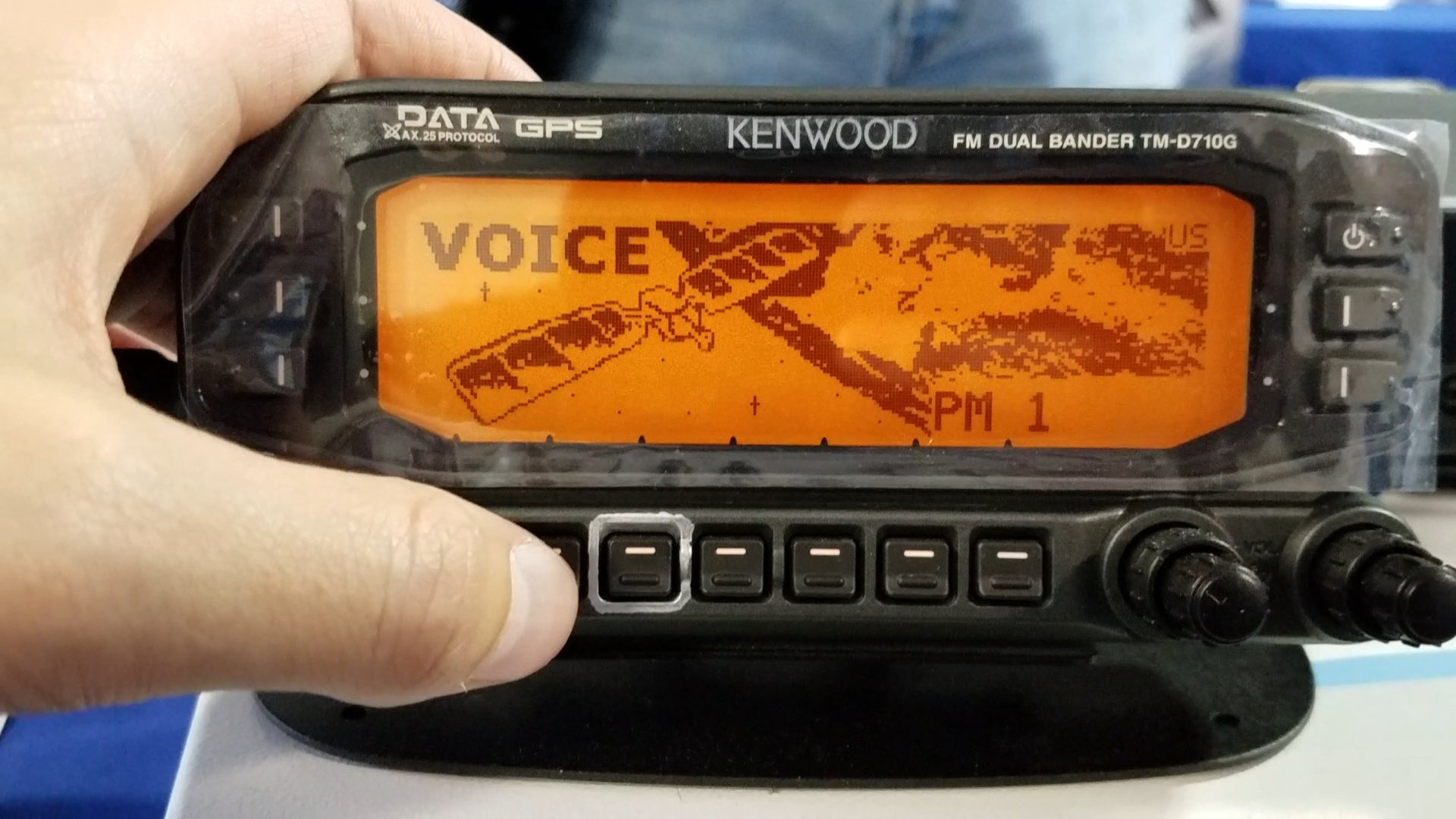

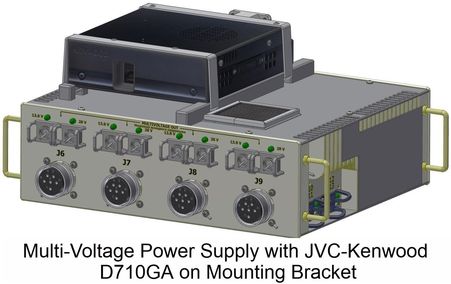

The IORS is the most complex in-cabin hardware system we have ever designed, built, tested and flown as a volunteer team. We will remove the 3 watt Ericsson handheld radio system, initially certified for flight in 1999, and the Packet module–both of which have recently had issues—and install a brand-new, specially modified 25 watt JVC Kenwood D710GA radio to enable a multitude of new or improved capabilities on ISS, including voice repeater and better APRS operations. A key development is the Multi-Voltage Power Supply (MVPS), which interfaces with multiple electric outlet connection types on ISS and provides a multitude of power output capabilities for our current and future ARISS operations and amateur radio experimentation. It will also allow our Ham Video system to have a dedicated power outlet, eliminating the outlet sharing we have now, which shuts down Ham Video at times.

This effort would not be possible without the dedication and persistence of our IORS development team of volunteers. They have been working tirelessly behind the scenes to provide an outstanding amateur radio experience for all. Our IORS development team includes: Lou McFadin, W5DID, our Chief Engineer; Kerry Banke, N6IZW, the MVPS lead designer; Bob Davis, KF4KSS, the MVPS Mechanical enclosure designer; Ed Krome, K9EK, supporting IORS thermal control and cabin noise dissipation; Dave Taylor, W8AAS, our JVC Kenwood D-710 development liaison; Bob Bruninga, WB4APR, our APRS and D-710 operations expert; Shin Aota, JL1IBD, and Phil Parton, N4DRO for all their phenomenal support from JVC Kenwood; Kenneth Ransom, N5VHO, our operations lead; and our safety package team—Ken Ernandes, N2WWD, and Gordon Scannell, KD8COJ. Kudos to all on a fantastic effort!

Designing, building and testing the IORS is a huge undertaking and *very* expensive. We need to build ten (10!) units to support flight hardware, flight spares, testing, and training across the international team. Hardware parts, development tools, fabrication, testing, and expenses to certify the IORS are expected to cost approximately $150,000. And the hard part (i.e. most expensive part) is just now starting. So please consider making a donation to ARISS to take our hardware system from dream to reality. You can donate to ARISS directly through the AMSAT web site at: http://www.ariss.org/donate.html. ALL donations go directly to ARISS.

Thank you for all your support to inspire, engage and educate our youth to consider wireless communications and amateur radio, and to pursue STEAM careers through our exciting human space exploration and amateur radio endeavor!

Ad Astra! To the Stars!

Sincerely,

Frank H. Bauer, KA3HDO

ARISS International Chair and ISS Ham Radio Principal Investigator

Source http://ariss.org/